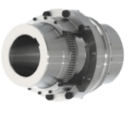

Gear Couplings

RUNFLEX Gear Couplings are meticulously engineered for applications demanding high torque, precision balance, and exceptional reliability. These couplings are crafted with a forged sleeve featuring internal gear teeth and two identical hubs with external gear teeth, ensuring efficient torque transmission from one end to the other. The innovative design allows the hub and sleeve teeth to remain in continuous contact, providing superior strength and stability while accommodating maximum angular, parallel, and axial misalignment.

Key Applications

- Cement plants

- Conveyors and Elevators

- Metal Rolling Mills

- Paper Machinery

- Cranes and Dredgers

- Rubber and Plastic Industries

Types of Gear Couplings

RFG SERIES

RHG SERIES

Features

Nylon Gear Couplings

RUNFLEX Nylon Gear Couplings are designed for smooth and reliable power transmission, even in demanding environments. These couplings consist of two steel hubs with crowned teeth, connected by a precision-molded nylon sleeve with internal teeth. The steel and nylon combination ensures excellent sliding properties, resulting in low maintenance and reduced wear

Key Applications

- Pumps and Compressors

- Conveyors

- Industrial Machinery

- Fans and Blowers

- Packaging and Printing Machines

- Agricultural Equipment